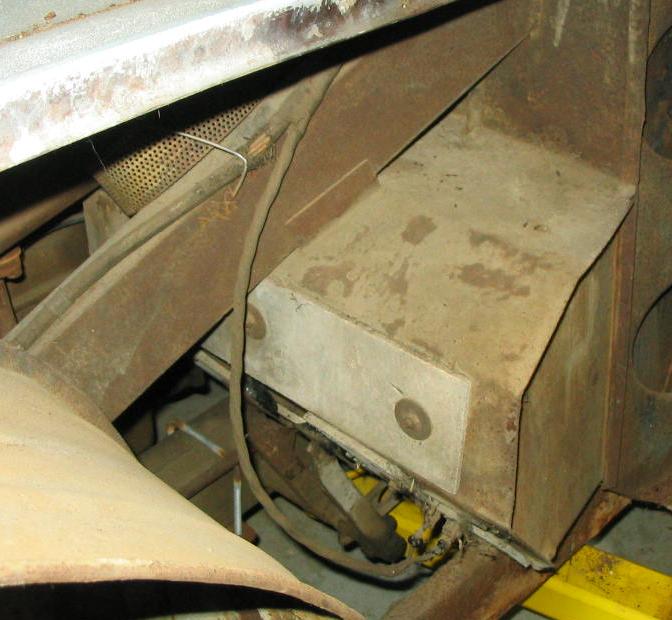

The drivers footwell heatshields on #174 were original and somewhat different from those that I have seen on later cars. These heat shields are installed on all “Big” Healeys to limit the amount of heat that is radiated onto the driver’s footwell from the exhaust manifold and down pipe.

The Original Heatshield on the Front of the Footwell

Footwell Heatshield Around Pedal Apertures

Footwell Side Heatshield

These heatshields are all made of the same asbestos material, with a pressed pattern on one side, that was used throughout later Healey production. Later 100s used a different material which is called “millboard”. Millboard is softer, a little more flexible and of layered construction. All 6 cylinder Healeys used the same material as was used on #174.

As is the case on Healeys that I have seen the material was not fitted with the pattern consistently inward, against the footwell, or outward. In fact on #174 of the two panels fitted around the pedals one was “pattern in” and the other was “pattern out”.

The heatshields on later cars were much more carefully shaped so as to cover the exposed areas of the footwell more completely.

Also of note, and peculiar to 100’s I believe, is the fact that no spacers were fitted between the material and the footwell to produce an air gap as was the case in the later cars.

#174, being a very early car, has some interesting differences in the types of fasteners used throughout the car. This was the period when many BSF threaded fasteners were still in use and quite a number of slot head screws.

Heatshield Fasteners

As can be seen in the photographs taken before the heatshields were removed the fasteners were all installed with the nuts outward so the slotted “pan” heads of the screws were all under the carpet in the footwell.

Also of particular interest is the way that the panel around the clutch pedal and around the dip “dimmer” switch has been broken away, probably during assembly at Longbridge, to provide adequate clearance.

I intend to reinstall these heatshields after painting them all over with latex paint to prevent their “shedding” asbestos fibers.

I would like to join the healey blue club? Have been

Restoring 291 since October 2019 starting to install

Heat shield looking for patterns on line ?

Hi Michael,

I’ve enjoyed reading through your blog which I just recently discovered. I’ve been restoring an early 100 (BN1L 147399 – car no. 714 – built Nov. 53) and have had a number of puzzlers that I couldn’t quite explain as well, like the paint. I purchased the car from it’s second owner, who purchased the car in 1958! He had never had it repainted, or done anything to it and didn’t believe the original owner had either, but there are a number of non-standard oddities that were either carried out before him, or were original (or maybe by the dealer). For instance, my heritage certificate states “healey gray” as the color; the outer portions of the car were “healey blue metallic”, but the all the hidden parts are that odd non-metallic blue-gray color you descibe, and was clearly the original color. Plus the aluminum boot and bonnet were replaced with steel, and the engine number didn’t match the plastic plate or certificate, but is only slightly later in the numbering scheme. Guessing that the dealer recieved the car with damage and replaced those items… not sure what else could account for the changes. Now I need to check the side vent holes!

Anyway, thank you for posting your blog, very entertaining and informative.

Sean Jeane

Santa Rosa, California

Sean,

Welcome to the Healey Gray Owners Club….I believe that you ae member number 3!!

It is quite remarkable that like #174 your car has a coat of “Healey Blue” over the original grey / blue.

I recently discussed the fender cut-outs with long experienced coach builder and he speculated that this work was done using a thin blade jigsaw of some type. The start hole being the round hole that I had speculated may be crack stop holes. That certainly sounds like the best explanation I have had so far.

Michael, I have Healey body number 449 it is Chassis 145525 Oct 53.

Randy hicks has given your contact info. The pics here are exactly what I was asking him. I also note there is no lug with rubber grummet holding the rising loom from the lower chassis, same as mine.

It’s great to have a contact with an early car.

Rgds

Bill Ingham

Melbourne