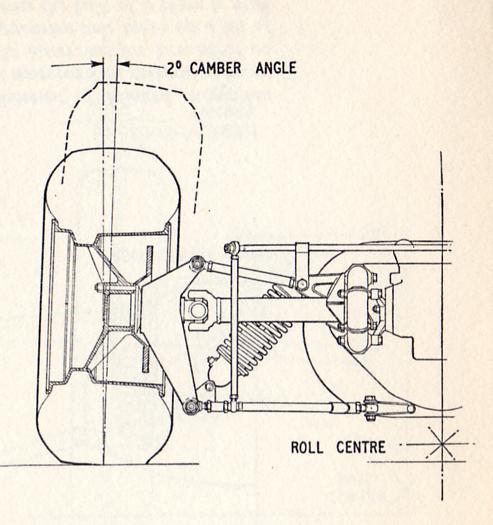

As the work on the conversion of AHX12’s rear suspension to coilovers proceeds I have been looking at other rear suspension systems for inspiration. One of the most interesting drawings that I have come across is that of the rear suspension used in the Lotus 33 F1 car of 1963.

This state of the art car used fully independent double wishbone suspension with the springs on an angle, similar to what I’m trying to do with AHX12. (I can assure you that the similarity ends right there).

The thing about this suspension type, which is used in many cars, and which has me most perplexed, is the angle of the springs. In the normal ride position the springs are inclined to the vertical and, as the suspension compresses this angle increases considerably.

At first glance this may seem a little unusual, but nothing to be particularly alarmed about. However, inclining the springs in this way, has a profound impact upon their effectiveness.

Let me explain. If the spring had a rate of 100 lbs/inch and was installed vertically such that its lower attachment point was the top of the wheel (ignoring for the moment of course the difficulty of actually achieving this) the spring rate would be equal to the wheel rate. i.e. if you pushed up on the wheel (the equivalent of adding weight to the car or going over a bump) with a force of 100 lbs the spring would compress one inch. Now lay that spring over at 45 degrees. In this case when you pushed up on the wheel with the same 100 lb force the wheel would move up 1.414 inches because the vertical force applied to the wheel by the spring is effectively decreased by the angle of the spring. Taken to the extreme if the spring was installed at right angles to the load it would have no effect at all.

Now let’s consider the Lotus 33. As far as I can determine the spring has an installed angle of something very close to 40 degrees in the normal ride position. This is in itself perhaps not to much of a problem however, when the suspension is fully compressed, the spring adopts an angle of something like 51 degrees. The results of this change of inclination, insofar as the effective spring force, is concerned is a decrease from .76 to .63.

The motion ratio of this suspension is about .66 , i.e. the spring is mounted to the lower wishbone 2/3rds of the way out. Presuming that the spring is a 100lb/in spring this means that the wheel rate is about .32 (.43 [motion ratio squared] times .76) at normal ride height and .27 at full bump. I trust you are keeping up here!!

The important point I’m trying to make here is that the wheel rate decreases by 15.5% from normal ride to full bump.

What I don’t understand is why they did this. It seems to me that a much more desirable condition would be an increasing spring rate as is provided by those wonky looking coil springs that you can buy with changing pitch, or arranging for the spring angle to decrease in bump!!

I can only presume that the decreasing rate was considered to be a reasonable trade off for simplicity and space savings.

All comments welcome (below).

Michael:

I believe that Lotus was focused more on roll than on bump. The roll center is at gound level causing maximum leverage over the CG. When the chassis rolls most of the force is applied to the upper interior location of the 4-link. The force is in line with the coil spring.

As Steve mentioned, the bump travel is only a few inches so that the regressive nature of the coil spring in bump is not as critical as the in line force of the coil spring in roll.

Best regards,

Jim

Hi Steve,

My thoughts on your points above.

1. Although that may be; the unresolved issue to my mind is that in a 2 wheel bump or say a sever compression I cannot understand why the spring rate decreases, this seems contrary to what one would want.

2. I would imagine that those were indeed progressive rate springs, because that is essentially what the currently available ones look like. I had no idea that they were available back that far.

3. Yes the teeter-totter front suspensions were used extensively and the springs in those could easily be arranged for increasing spring rate without having to resort to a special spring.

4. I need to watch that movie again. BTW a friend on mine once owned the Lola T70 which was converted into a camera platform for that movie. Only car I’ve ever drive which could lift its front wheels off the ground under acceleration…scary!!

Comments/Questions:

1) on the underside of the roll, when the spring’s weaker, maybe the anti-roll bar compensates for it.

2) if I recall, some motorcycles in the early 60’s used springs that were closer-wound at the top–are these progressive?

3) a few years later, on the front, Lotus used a teeter-totter upper A-arm where the inside arm compressed the spring–did they ever use this on the back?

4) the drawing shows a lot of travel in the suspension, but when you watch the movie, Grand Prix, it seems like the suspensions are only moving an inch or two.

FWIW

Steve Gerow

I wasn’t aware that that was an option Dave, but my quandary is “Why did Colin do this in the days before such springs were around?”

Coil springs can be easily made to have a rising rate, which would compensate for the leverage change, or even over compensate if that is what is desired.

Dave R.