Any comments in the space provided below would be welcome.

After fighting with the cart springs on the back of AHX12 and other Healey race cars for many years I have decided that the time has come to get this monkey off my back once and for all. The rules for the modified class for Targa Newfoundland permit changing the type and positions of the springs and shocks, but prohibit replacing live rear axle with an independent rear end.

Although it would appear that a De Dion system would be permitted the work involved in designing and developing such a system appears to be a little daunting to say the least.

I have decided to stick with the old spiral bevel BN1 type axle for the present (read watch this space) and build a four link system incorporating coil-overs which will decrease the unsprung weight at the rear by quite a bit and give me a degree of adjustability which is unobtainable with the original Hotchkiss system.

I intend to build a small subframe assembly just forward of the differential which will be welded to the main chassis rails. I will use the upper radius arms which duplicate the BJ8 style and add lower arms to replace the leaf springs.

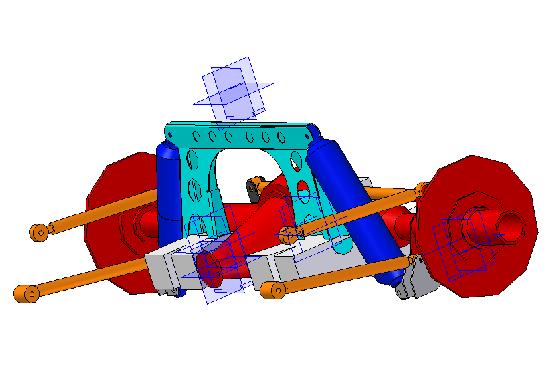

The finished job will look like this, although in this rendition I have drawn the coil-overs as the blue shocks because the springs take so long for my computer to render.

In addition to this I have modified the rear chassis to incorporate a dip much in the style of the BJ8.This modification will allow an extra 1.75” of rear suspension travel, something desperately needed for big bumps and “landings” in Newfoundland.

One problem that a four link system can present is incorporating anti-dive / anti-squat into the design without producing chassis roll induced oversteer. To put this into more simple terms it is desirable to design the suspension such that the car does not nose down on braking or nose lift on acceleration. These reactions, which can be quite significant, tend to destabilize the car and make control in extreme situations difficult. Modern suspension systems incorporate geometry which reduces or eliminates dive and squat and this is what I intend to do to achieve this.

At normal ride height I have designed the arm positions as above.

Under acceleration the diff housing will tend to rotate clockwise. This action will produce a tension in the upper arms the vertical component of which will tend to lift the chassis producing the anti squat. Should the car actually take on some squat (i.e. chassis moving away from the axle) the angle of the upper arms will increase and therefore the relative vertical component of the tension in them will also increase to minimize the squat. The angle of the lower arms will also increase and the vertical component of the compression in them will tend to induce squat, however the rate of increase of this force will be lower than that of the upper arms producing a net lifting force on the chassis.

Under braking the diff will tend to rotate anticlockwise and the vertical component of the compression in the upper arm will tend to force the chassis down. Should the chassis actually rise relative to the axle (dive) the vertical component of the tension in the lower arm will end to pull the chassis down replacing the force lost by the decreasing angle of the upper arms in a similar fashion to the squat scenario described above

The big issue however is the fore and aft position of the axle in a turn.

This is how I see this scenario.

If the chassis moves closer to the axle (suspension compressed {outside of turn}) neither arm will adopt an angle which will move it nearer to horizontal; thus they will both effectively become shorter. These arms becoming shorter will move the axle forward on the outside.

If the chassis moves away from the axle (suspension extending {inside of turn}) the upper arm will become closer to horizontal increasing in effective length as the lower arm gains angle and becomes effectively shorter. These length changes will near enough cancel each outer out resulting in no change of horizontal position of the axle on the inside. I realize that the axle will have a tendency to rotate different amounts at each end under this scenario but I think the rubber bushings used on the forward ends of the lower arms will have sufficient compliance to accomodate this

My expectation is that the nett result in a turn will be that the outside end of the axle will move slightly forward while the inside stays close to its neutral position the result of which will be chassis roll induced understeer which is what I want to achieve.

Hi Michael- I’ve enjoyed reading about the progress of your car. I’ve got a BN4 project and a Ford OHC 2.0 (pinto) powered 100-4. I also have a few Fiat 124’s (spider and coupe). Take a look at the rear suspension of the Fiat 124 Spider and you’ll see a similar setup to the one you’ve proposed- parallel trailing arms, coil springs, panhard rod. Seems to work pretty well, even for the racing crowd.

Good luck!!

Austin

I erred previously–Alfa 2 liter rear ends are typically 10/41 or 4.1.

Hi Mike,

FWIW–maybe an Alfa Spider rear end would rate a look?

It has an all-aluminum center section. Typically 4.56. Lower links and an upper t-bar linked to a ball joint on one side of the diff. Should be cheap. Don’t know if they can handle 200 hp, though there are plenty of Alfa racers around who would know.

Also I notice Summit Racing sells really nice Granatelli Mustang adjustable control arms–either with heim ends for race or urethane for street. Don’t know what the length is , though. Wish I’d thought to search for those before I bought my non-adjustable BJ8 arms from Cape for big bucks. Quite a few adjustable arms come up on Google.

Am enjoying the blog! Likewise happy New Year.

Hi Michael,

Glad you enjoyed the blog submission.

Regarding the Elva rear end I really couldn’t comment on the concept of “maintaining better contact”. If by this he is hoping that this may help the inside wheel stay on the ground better that would depend on several factors.

The big problem with having the upper arms slope down toward the axle is that as the suspension compresses on the outside of the corner the axle will move back on that side and as it extends on the inside the axle will move forward there. With a beam axle this has a very undesirable effect in that it steers the car into the corner (oversteer). Not good as can be seen from the video on my earlier post of AHX12 going down into the boot at The Glen.. as they say…”only his laundry man will know”!!

Have a great New Year.

Michael–

Thanks for another thought-provoking post. I have a four-link rear on my Elva Courier and the upper links angle down somewhat toward the axle as opposed to slightly below horizontal as you have designed. In fact a friend who has considerable racing experience has suggested that I consider lowering the frame mounts so that the upper links are closer to or at level, saying that this will in effect force the rear suspension into better maintaining contact. I realize I am asking a rather generic question regarding a specific situation but does this comport with your thinking?

Hope you and yours have a great New Year.

Best–Michael Oritt