Back in the days when I was a really poor British sports car mechanic I managed to pick up a Suzuki LJ80V all-wheel drive van with a badly slipping clutch to use for winter transportation.

It was a horrible little thing but great in the snow and all I could afford at the time. Before I could use it I had to replace that clutch and in doing that job my opinion of Japanese design improved immeasurably. The only tool required to change the clutch, which required that a gearbox with a 4WD transfer case be removed, was one 13 millimeter wrench. ONE!!!

For a guy who was accustomed to using almost every tool in his 15 drawer tool cabinet and a few borrowed ones just to change a fan belt in an MGB this was a revelation and made me realize just how far the British motor industry had to go in 1953 when they started producing the Austin Healey 100.

From the manufacturers perspective such simplicity can produce extensive benefits because not only is the vehicle easier to construct and service but the parts inventory required both for construction and after sales service is dramatically reduced.

1952/3 must have been interesting and challenging times for the Austin engineers as the Longbridge factory was geared up to produce the new Austin Healey 100. Britain was desperate for overseas sales but their factories were old and funds for new machinery and imported materials were just not available.

Unfortunately as a result of the shortages the new car had to use an old power train. The engine, with two cylinders lopped off, was a copy of a pre-war six cylinder Bedford lorry power unit which had been adapted from a 1929 Chevrolet design. There was no time or money to “modernize” the engineering so it was still being produced with outdated British Standard threads, British Standard Fine (B.S.F) and British Standard Whitworth (B.S.W) at a time when all new designs were being produced using the modern SAE thread system of Unified National Fine (U.N.F) and Unified National Course (U.N.C.). This was not ideal situation but there really weren’t any viable alternatives.

However, if the engine was not exactly “start of the art”, the gearbox was even less suitable for the latest in sporty motoring vehicles. Adapted from a column change saloon car “cog box” it was never designed to handle even the modest 144 lbs. ft. of torque delivered by the lump ahead of it but, again, it was all that was available within the budget so it had to be used. I suspect another factor was that Len Lord the president of the newly formed British Motor Corporation had hundreds of them lying around as a result of the Austin Atlantic disaster.

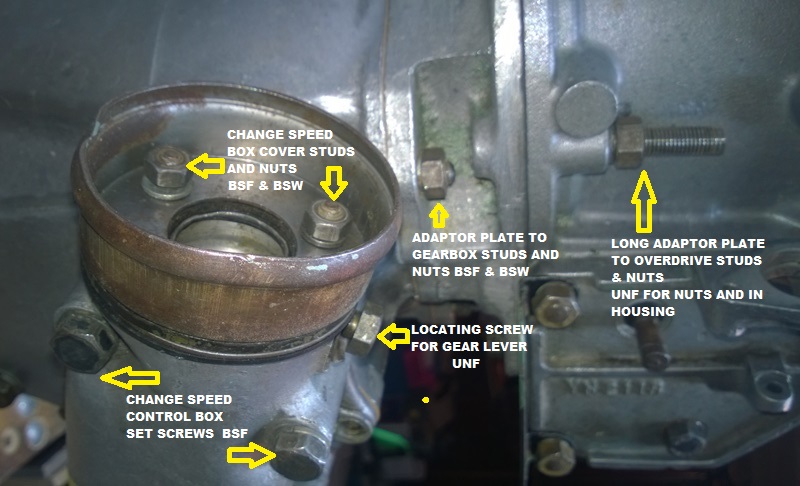

Studying the threads used in this gearbox gives us an idea of the lengths the engineers at Austin needed to go to in their efforts to get those Healeys out the door.

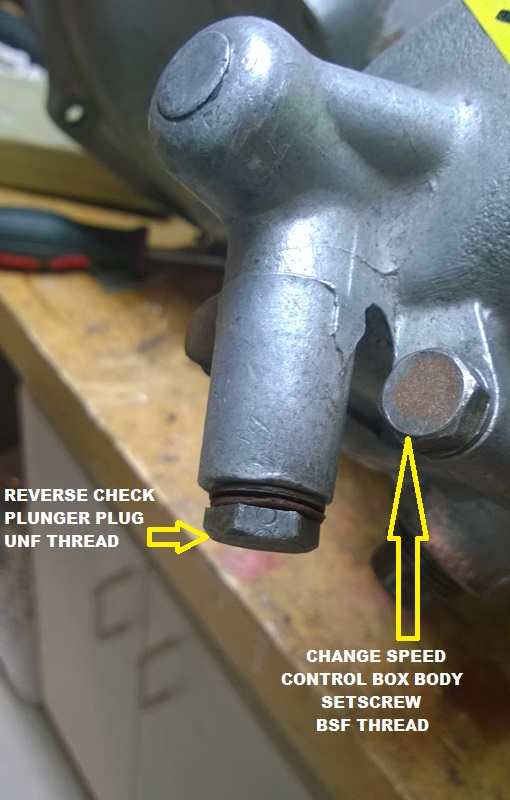

The starting point was a 4 speed box designed to be used in vehicles like the Austin 16, a staid family car with barely enough power to “pull the skin off a rice pudding” as my Dad used to put it. The first job was to come up with an inexpensive way to produce a floor shift as no self-respecting “sports car” could have anything resembling the “three on the tree” gear change that the gearbox was designed around. This was achieved with a nifty adaptation of the original gearbox side cover and the addition of an Austin Taxi “change speed control box body” upon which a gear lever could be pivoted.

Everything worked out just fine but the threads… oh my, the threads.

The interesting thing about this “change speed control box body” is that within the design of this small cast part 3 different threads were used and that is just the beginning!

It was found that because of the 4.125/1 Austin Healey differential ratio (another saloon car legacy) 1st gear in the four speed box was useless and reputedly produced “nothing but wheel spin with anything like a spirited take off.” (See note below). The solution was that the 1st gear in the box would need to be blanked off producing a three speed gearbox.

One can only imagine the wails of anguish from the marketing department as no sports car of the day could be sold with a three speed gearbox even if it was all synchromesh … an overdrive unit was required. Fortunately the Laycock-de Normanville unit selected was a modern design which used U.N.F. and U.N.C. threads.

This clever addition appeased the marketing department but really complicated the thread issue as it required an adaptor plate with BS threads on one side and SAE threads on the other; not a design achievement that any engineer could be very proud of.

As a further complication the overdrive unit required a plunger switch on the side of the gearbox to prevent the overdrive being engaged when the gearbox was in reverse as doing so would destroy the overdrive unit. Enter Joseph Lucas. Now Joe was a very traditional guy and, apparently, a big fan of BS threads which the Lucas Company stuck with right through into the 1970’s so the switch he supplied used yet another thread form namely British Association (B.A.).

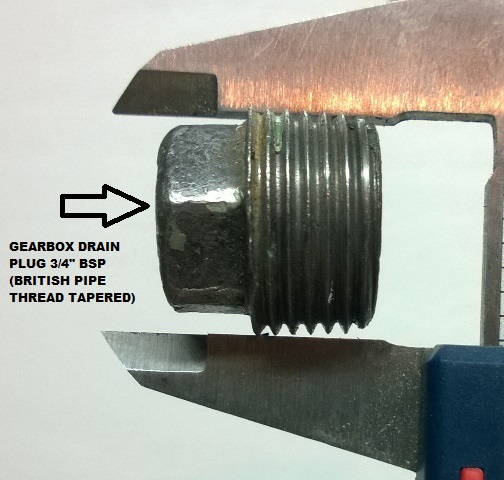

So now we have five different threads in this unit; B.S.F., B.S.W., U.N.F., U.N.C., and B.A….but wait… there’s more! We have to consider the drain plug for the gearbox.

Rather than use a standard parallel thread screw with a soft washer under its head the gearbox incorporated yet another thread system British Standard Pipe (B.S.P), which is tapered, in order to stop the oil from leaking out and to save the cost of a sealing washer.

Surely at this stage the engineers must have been tearing their hair out; six different thread standards in one gearbox unit but we aren’t finished yet.

As a grand finale the box incorporated this 1 7/16” LEFT HAND THREADED nut with fourteen threads per inch to lock the front bearing of the gearbox onto its shaft. As far as I can figure there is no “standard” for this gem.

Seven different thread forms in one gearbox unit that’s quite an achievement. You can see why I was so impressed by the Suzuki.

Note.

I have a theory about why the 4.125/1 rear axle ratio was used in the 100.

Geoffrey Healey states in “The Healey Story” that ”Austin did not have a high* enough gear ratio for the A90 rear axle” but that is not strictly correct. The Austin Atlantic convertible used a much better 3.66/1 ratio which, incidentally, was even offered as an option on the 100 and a 2.92/1 and even a 2.69/1 ratio became available in the 100S and those cars used the same rear axle housing .

Conventional wisdom has it that the 1st gear in the BN1 gearbox was too low and produced excessive wheel spin but I think that is a marketing myth. Donald Healey in “My World of Cars” states “The only disappointing part of the A90 was its gearbox, which was not man enough for the job in a sports car”.

My bet is that it was discovered early on that the torque of the engine was just too much for the gearbox and “The New Austin Healey 100 with enough torque to rip the teeth right off its 1st gear” didn’t sound like a winning slogan. The decision was made to stick with the lower diff ratio, which meant that 2nd gear starts were satisfactory, and “block off” 1st gear in the interests of reliability. Unfortunately that limited the top speed to 90MPH at maximum RPM, a problem solved by fitting an overdrive unit.

* A “high ratio” differential has a low ratio number whereas a “low ratio” has a high rati0 number.

Hi Michael-well presented! That gearbox is so much fun to deal with showing just how poor UK was after the war and how everything was make due.

I did not realize the LH nut was 14-yes, another great solution. I use Hylomar on the drain plug as the pipe thread still leaks-yea, all for the sake of a washer.

I would be interested to hear your comments if you get a chance to read our May/June Austin-Healey Magazine-I have an article on Coronet Cream-as per the car you last restored. Good to hear from you. Regards, Hank

Michael–

As always an interesting and well-written article.

Second gear on my 100’s 3-speed broke when I was at the turnaround point of a 2002 road trip from Maryland to California and back. I just couldn’t see doing the return with only first and third/third overdrive so I bought from Smith Brody a Smitty’s Toyota 5-speed conversion kit and a transmission that he (Smitty) had on hand and with a lot of help and the use of his lift drove out two days later and made it back to MD without a problem.

I know this modification might be anathema to many–perhaps even you–but it made the 100 into a much more tractable and driveable car. It is one I have never regretted.

Best–Michael Oritt

Great article and remember it well when 2nd gear “chipped” the night before an RAC rally!!